| Min Batch Capacity |

3/4" layer,

1/20 cubic foot,

or 1/3 gallon

|

19mm layer,

1.4 dm3,

or Liter

|

|

1"-layer

1/8 cubic foot,

or 1 gallon

|

25mm layer,

3.5 dm3, or

3.5 Liters

|

|

1" layer,

3/8.cubic foot,

or 3 gallons |

25mm layer,

11 dm3, or

11 Liters |

|

1" layer,

3/8 cubic foot,

or 3 gallons |

25mm layer ,

11 dm3, or

11 Liters |

|

| Max Batch Capacity |

1-1/2" layer,

1/10 cubic foot,

or 3/4 gallon

(10 pounds)

|

38mm layer,

2.8 dm3,

2.8 Liters,

(4.5 kgs)

|

|

4-3/4" layer,

5/8 cubic foot,

or 5 gallons,

(65 pounds) |

120 mm layer,

18 dm3,

18 Liters,

(29 Kgs) |

|

4" layer,

1-3/4 cubic foot,

or 13 gallons,

(175 pounds) |

100 mm layer,

50 dm3,

50 Liters

(79 Kgs) |

|

4-1/2" layer,

2 cubic foot,

or 15 gallons,

(200 pounds) |

112 mm layer,

57 dm3,

57 Liters,

(91 Kgs) |

|

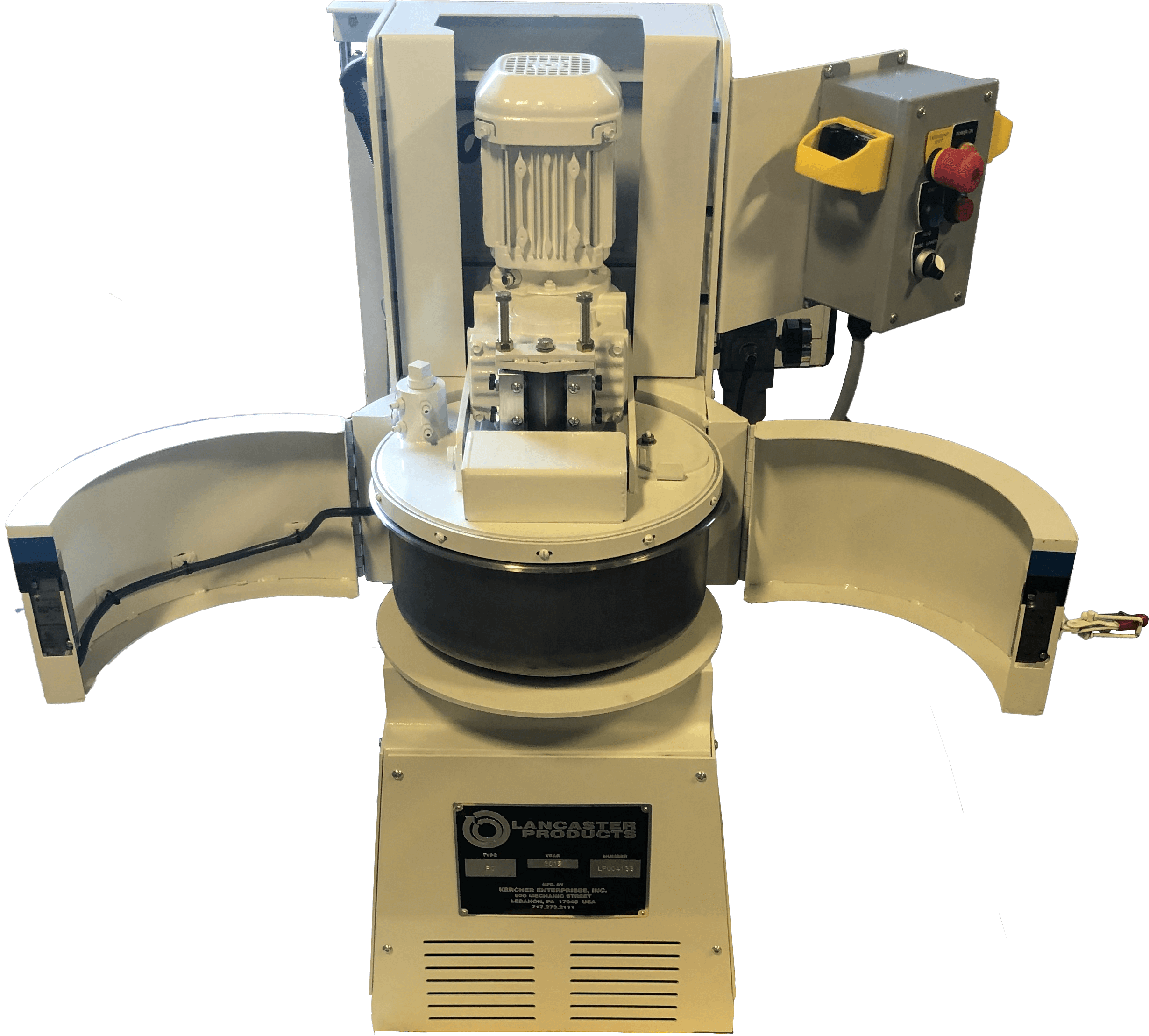

| Mixing Pan |

12" diameter

5" H |

305mm diameter

127 mm H |

|

18" diameter

8.5" H |

457mm diameter

216 mm H |

|

29.5" diameter

11" H |

749mm diameter

279mm H |

|

29.75" diameter

14" H |

756mm diameter

356mm H |

|

| Mixing Pan Power |

Direct Connected

1/4 HP

gear motor

3/60/230-460V |

Direct Connected

0.18 kW

gear motor

3/60/230-460V |

|

1 HP

gear motor

3/60/230-460V |

0.74 kW

gear motor

3/60/230-460V |

|

3 HP

gear motor

3/60/230-460V |

2.2 kW

gear motor

3/60/230-460V |

|

3 HP

gear motor

3/60/230-460V |

2.2 kW

gear motor

3/60/230-460V |

|

| Mixing Pan Discharge |

removable pan |

removable pan |

removable pan |

central discharge |

| Tooling Power |

Direct Connected

1/4 HP

gear motor

3/60/230-460V |

Direct Connected

0.18 kW

gear motor

3/60/230-460V |

|

Direct Connected

1 HP

gear motor

3/60/230-460V |

Direct Connected

0.74 kW

gear motor

3/60/230-460V |

|

Direct Connected

3 HP

gear motor

3/60/230-460V |

Direct Connected

2.2 kW

gear motor

3/60/230-460V |

|

3 HP

gear motor

3/60/230-460V |

2.2 kW

gear motor

3/60/230-460V |

|

| Size |

16" W

30" D

40" H

325 pounds |

406mm W

762mm D

1M H

147 kilograms |

|

23" W

32" D

58" H

1100 pounds |

584mm W

813mm D

1.5M H

500 kilograms |

|

32" W

59" D

71" H

1850 pounds |

813mm W

1.5M D

1.8M H

839 kilograms |

|

35" W

67" D

78" H

3000 pounds |

889mm W

1.7M D

1.2M H

1,361 kilograms |

|