Lancaster Products Rotary Table Feeders convert intermittent batch processes into a continuous material feeding process.

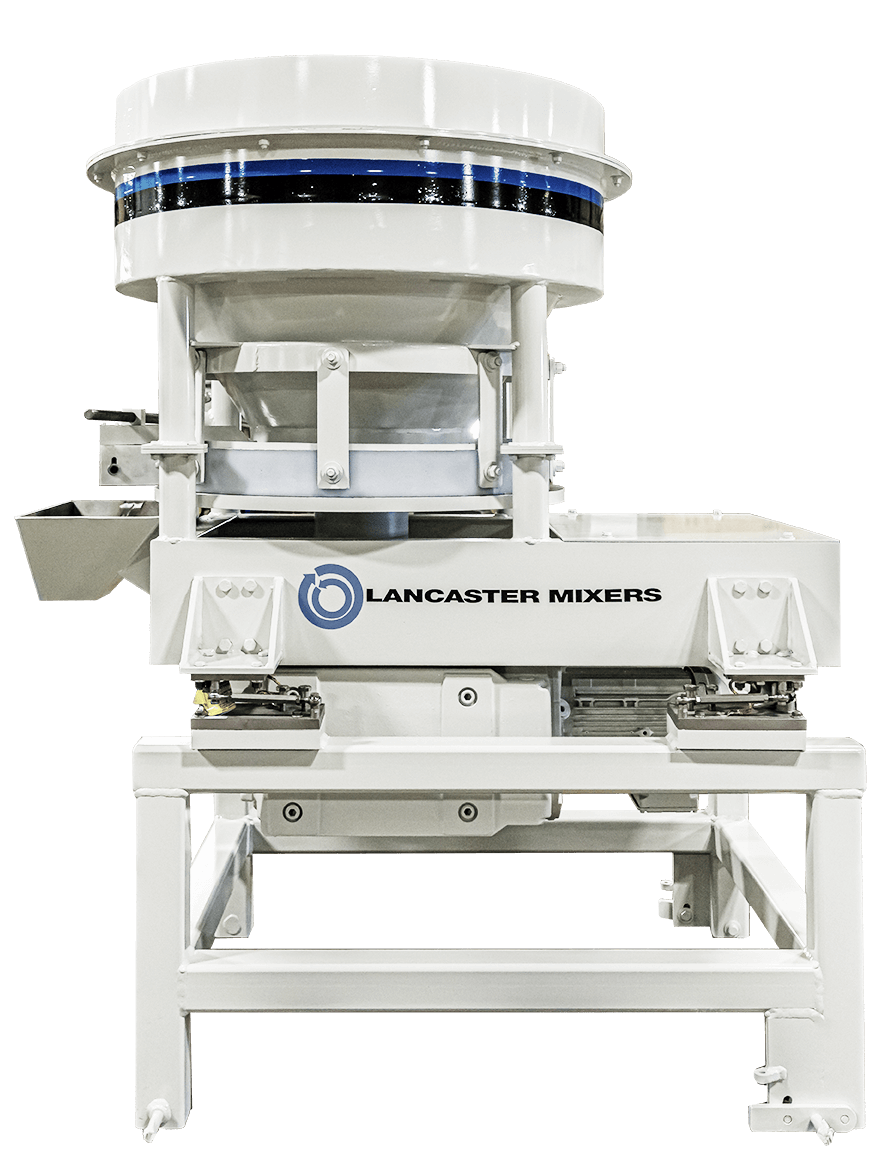

Lancaster Products Rotary Table Feeders are very useful in converting an intermittent batch process into a continuous material feeding process, increasing production rates while maintaining product accuracy, consistency and higher yield outputs. Variable flow rates can provide even flow of material from the table feeder to your downstream processing equipment.

THE LANCASTER TABLE FEEDER ALSO EXCELS AT MOVING STICKY OR HARD TO FEED MATERIALS.

KEY FEATURES

Variable flow rates

Use with difficult flowing materials

Gentle handling of green or weak materials

Prevents material bridging

Bin discharging applications

Converts batch processes into continuous process

Custom table diameters and storage volumes available

VARIABLE FLOW RATES

The flow rate is adjusted by changes in the angle of the discharge plate and table rotation speed – turning an intermittent process into a continuous flow process.

The amount of material leaving the table feeder can be controlled by changing the angle of the discharge plow either manually or automatically. The feed rate can also be controlled by using a variable speed table drive motor to adjust the speed of the bottom rotating table.

USED WITH DIFFICULT FLOWING MATERIALS

Lancaster Rotary Table Feeders are particularly helpful in moving sticky or hard to feed materials. Powders, fibers, flakes, and pellets are all handled easily and efficiently. The feeders gently transport delicate materials such as green pellets that could be damaged by other material transport methods. The rotary action of the feeders prevents bridging of hard to feed materials. We often close couple table feeders with our Lancaster High Shear Counter-Current Mixers to change the batch processing of mixer to a continuous process.

BATCH TO CONTINUOUS PROCESSES

The table feeder can also convert a batching process into a continuous process. The cone and cylinder over the table is then used as a surge hopper to temporarily store the material batch while the table feeder continuously discharges the material.

BIN DISCHARGING APPLICATIONS

The Lancaster Table Feeder attaches directly to the bin walls forming the bottom of the bin. This allows some of the most difficult flowing materials to be evenly fed from the bin. The cone and cylinder over the table are then used as a surge hopper to temporarily store the material batch while the table feeder continuously discharges the material. The entire assembly is known as the live-bottom bin.

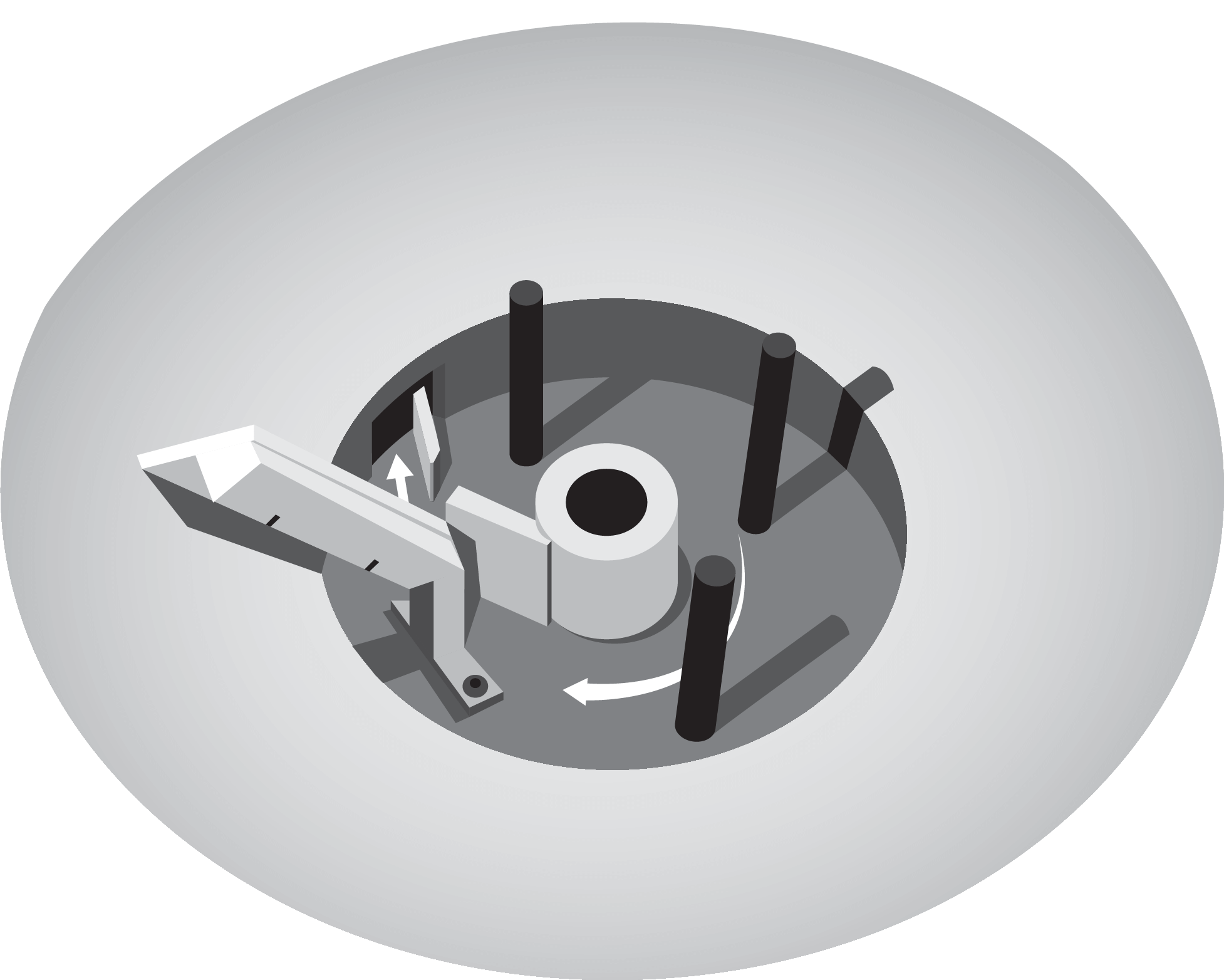

HOW IT WORKS

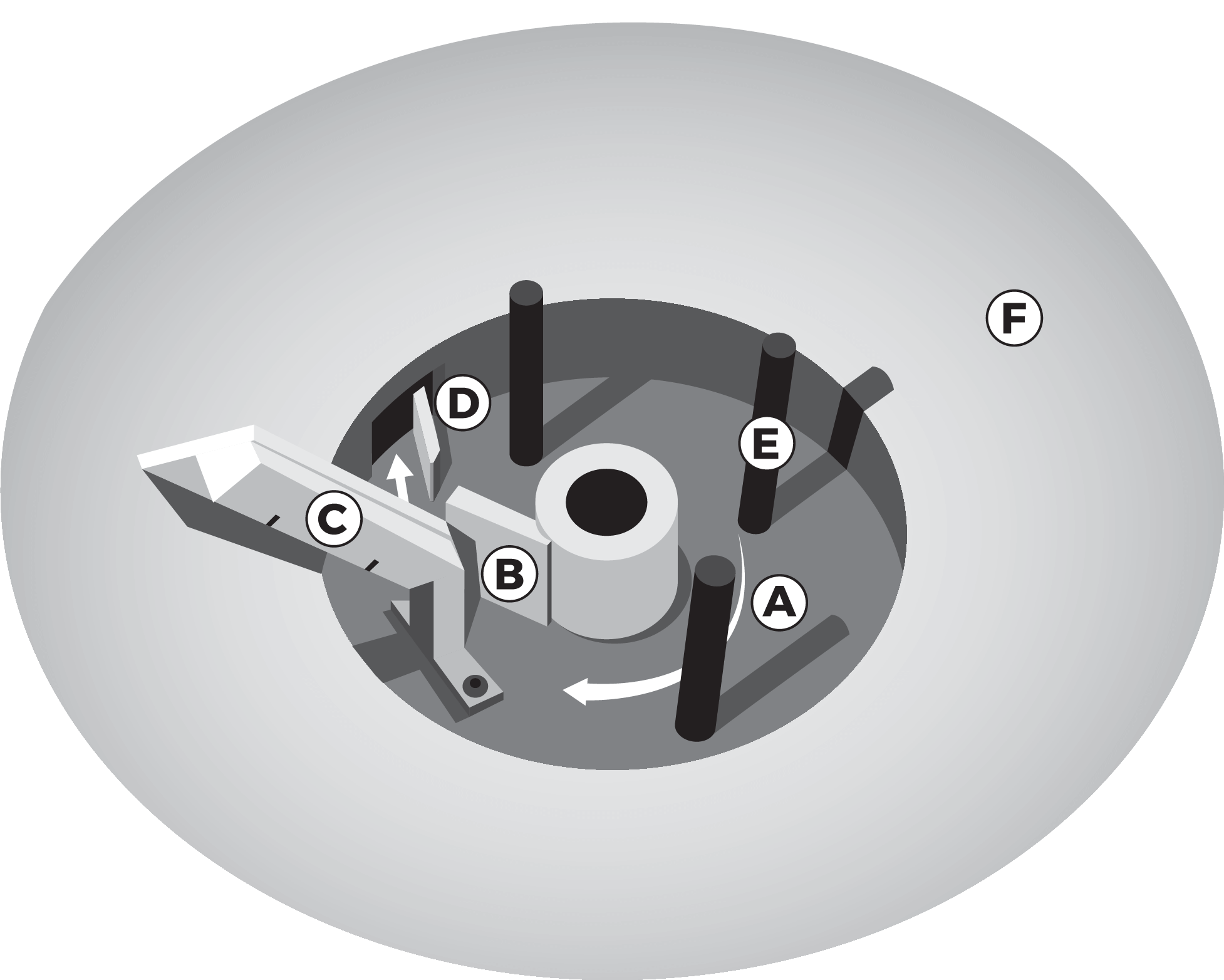

The Lancaster Rotary Table Feeder uses a large flat rotating table to continually bring material from the cone to the discharge plow. The table has vertical pins attached inside the cone area.

There is also a cone scraper blade attached to the table. As the table turns, the blade and pins agitate the material and keep it evenly flowing to the discharge plow. An adjustable seal band rides on the outer surface of the table to prevent material from exiting the table feeder outside the discharge area. The discharge plow is used to bring the material to a fixed point as it leaves the table.

The rotating pins and the inner rotating plow provide a constant feed of even the most difficult materials.

A – Direction of Rotating table

B – Stationary plow to clean inner area of table

C – Rotating scraper blade

D – Adjustable plow directing material flow out of table feeder

E – Vertical pins to agitate material for even discharge

F – Transition cone

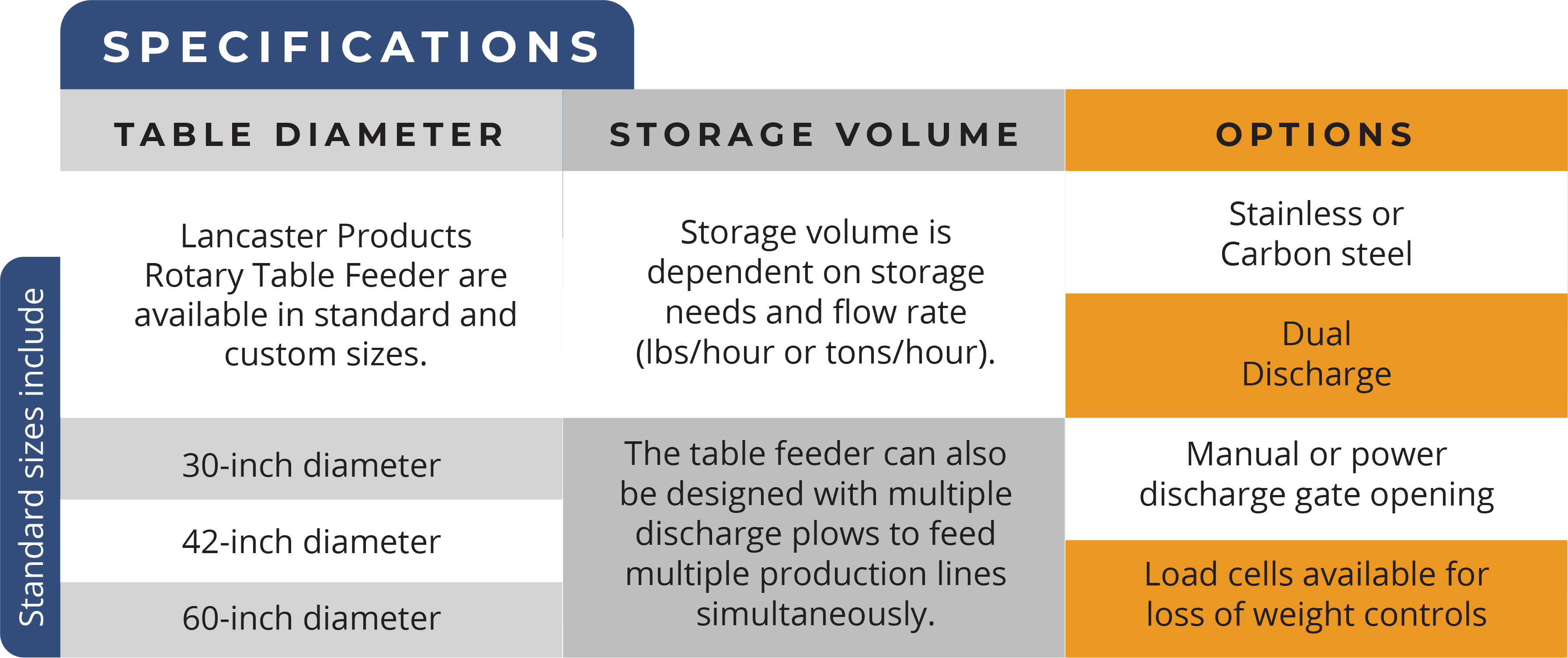

SPECIFICATIONS